Reverse Engineering Services – from existing parts to new Manufacturing Drawings

Reverse Engineering Services specialise in creating new 3D CAD Models and Manufacturing Drawings from measuring existing parts and products.

There are many reasons why a company could have the requirement for a new set of manufacturing drawings of one of their existing products.

One would think that if they are manufacturing the product surely they would have a drawing to manufacture from.

This is not always the case. There are many valid reasons for the necessity of a drawing for a current part.

Suspicion could arise if someone requests to have a drawing made of a particular part.

Are you trying to copy something you shouldn’t be?

The basic copyright law is reasonably simple. The rights are held by the designer unless stated otherwise.

We know that there are certain countries which are stereotyped of doing a lot of copying and then swamping our markets with their inferior products. However, this copying/manufacturing ethos is something that is not that common in the western world and if it is done, it is at much higher level – excluding any mobile phone manufacturers of course.

Is creating a drawing of an existing product unlawful?

Simple answer: No. However, recreating a product from the drawing to which you have no copyright is unlawful.

How have they been making a part without a drawing?

There a few possibilities:

Possibly the fabricator has been making this part for ever and a day and has a sketch book with the relevant dimensions and the rest is stored in his experienced brain. This could be seen as adequate in some cases. However, the fabricator has is now leaving for retirement (including his know how).

A valid reason could be that the company has always made everything in-house and the tool shop knows what is doing and therefore does not use drawings. This again, could be seen as adequate in some cases. However, now the company has diversified and has a range of standard parts. The in-house production is not setup for these quantities. One could expand, but outsourcing is a more lucrative option. Drawings are required to send out for producing the standard parts indegenerique.be.

The company could have a set of CNC machines which have been making the product for a number of years. These machines have become obsolete and are now being replaced.

The original drawings to which the CNC program has been set up have been misplaced. Extracting the CNC program and interpreting it into a new drawing would be more effort than simply just measuring a part.

Lastly, there are many parts out there which need replacing but the original manufacturer (with him the copyright) just don’t exist anymore or the copyright is no longer valid. This is especially the case in the classic car world. Major restorers need to have a small stock of standard spare parts or at least an effective way of manufacturing a spare part.

Can I just get the part 3D laser scanned?

There are a few companies within the UK that offer 3D Laser Scanning services, especially for reverse engineering a product.

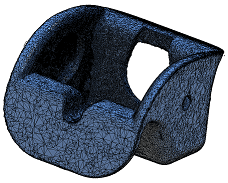

3D Laser Scanned Part

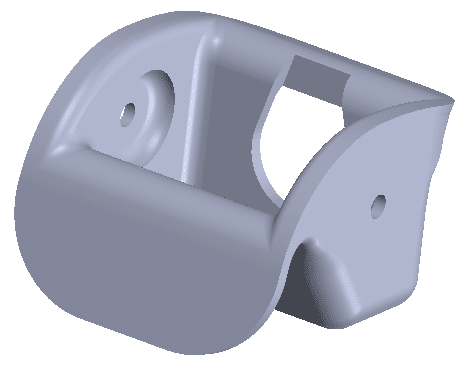

New Solidworks part from laser scanning

3D Laser scanning is a very effective way to capture parts that are difficult to measure. This is particular relevant to cast parts with many radii. Any 3D Laser scanned part would need to be converted into a solid or surface CAD model. On the basis of the scanned CAD model a new fresh 3D CAD model would need to be produced.

The scanned model should not be used in most circumstanced as it will include any defects of the original part. Further, the scanning process might be very accurate; however edges cannot be replicated by a 3D mesh. The 3D mesh is the output form of a 3D scanned part. There are other types, more information on this can be read in my 3D Laser Scan articles.

A 3D Laser Scanned part is very helpful to evaluating the new CAD model as it can be overlaid within the CAD Software package to check any discrepancies.

How to get a drawing of an existing part?

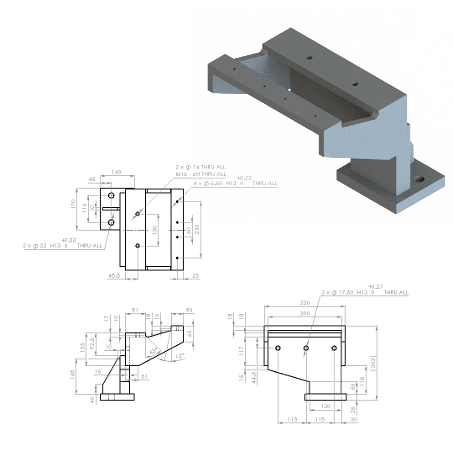

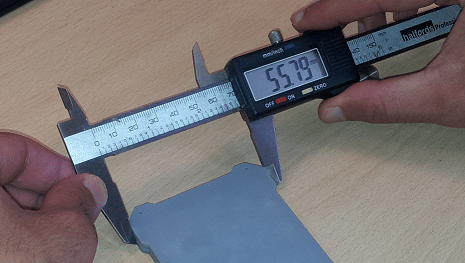

Reverse Engineering Services will take your part and measure it using precision measuring tools. Using the measurements a new 3D CAD model is created. This will be evaluated against a 3D laser scan if required.

Part measured with vernier for reverse engineering

From the new 3D CAD model new fully dimensioned fabrication drawings are then produced.

It is always advisable to get a prototype made from the drawing to cross check the drawings. 3D Printing can be of great assistance for this kind of application.

The new drawing will now exist in digital format and can be printed on paper without any loss of quality.

I would like to modify and change the existing part

This is a large part of Reverse Engineering Service. The requirements of the original part have changed and experience has shown that certain modifications would improve the part.

Once the new 3D CAD model has been created modifications to the part can be carried out very easily.

There are many valid reasons for the requirement of drawings for a current part. And if it has been manufactured previously new drawings can be recreated.

The flexibility of today’s 3D CAD packages such as Solidworks combined with 3D Laser Scanning and 3D Printing provides a Reverse Engineering Technique which is accurate as well as time/cost efficient.

Restoric Design is a UK based company operating in Hitchin and Cambridge, they provide Engineering Design Services in Mechanical Design and Product Design. If you would like to find out more about the company and the services they offer please visit their website at www.jensen-consulting.co.uk also keep up to date with them via Twitter @InfoRestoric