To coin a slight spin-off of a well-known phrase, the devil is in the detailing. This is impossible to ignore when talking about safe, sturdy building structures. Effective design and structural analysis combine with extensive structural steel detailing to ensure that after a construction project is executed accurately and there will be no cracks or deflections in the building. No one wants to be facing the worst-case scenario of a collapsed building.

The process of steel detailing usually begins after a contractor is assigned to a project, and it is usually developed in great depth by rigorously working on 2D drawings. But bringing in structural detailing at this point sets in motion a process that is hampered by its late start, and frequently results in poor coordination between stakeholders that can put construction schedules at risk.

The means by which we can avoid these kinds of difficulties nowadays involves using advanced software tools to develop complex steel fabrication drawings. The primary advantage of this is that if one starts steel detailing after the design phase, based on the drawings of a structural designer, it is less difficult to coordinate the steel with the structure and improve the efficiency and effectiveness of the construction process.

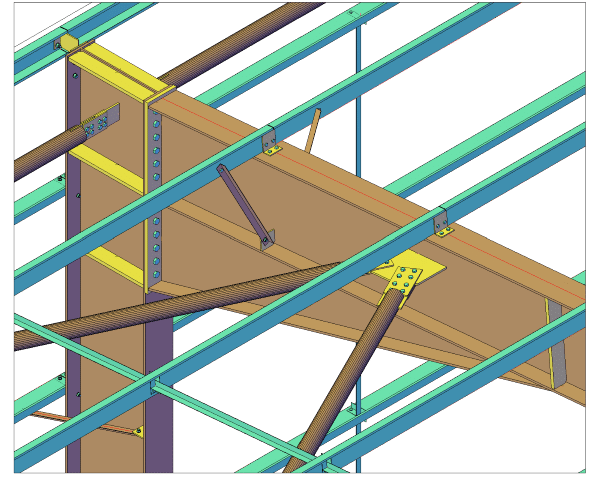

Steel detailing software is about more than just project coordination, however. It assists in the enhancement of the overall standards of steel structures. In a 3D modelling environment, teams can design independently and deliver project fabrication materials in an efficient and cost-effective way. This approach, based on modelling, enables teams to avoid some of the old complex design issues by reaping the benefits of 3D views and real-time schedules to check steel.

Wave goodbye to project schedule delays

Steel detailing software enables every drawing sheet, 3D and 2D view and schedule to be displayed as an actual presentation of a designed building’s underlying structure. Automated synchronisation is at the heart of every good CAD programme, so all the drawings and views involved in the design process are well managed and synchronised accurately. So if you need to make changes to the steel design in a model, it will be reflected in your fabrication drawing, meaning you cut down on the tedious process of updating everything manually.

Keeping costs down

It is always of paramount importance that you keep costs at a minimum – after all, who doesn’t enjoy maximum rewards from a project? With steel detailing software, you can swiftly calculate alternative models that will meet your requirements at a minimal cost. The software will help you estimate the amount of steel necessary, and even auto-generate a bill of materials, saving you on both material expenses and labour.

On-site problems are minimised

With a model-based projection incorporated into your fabrication drawings, there is virtually no risk of on-site issues arising that will impact schedules or require you to redraw. A steel model can be viewed from any angle you require, and you can monitor things on-site through the software to maintain a good understanding of the construction process.

By outsourcing the steel detailing to a CAD consultancy like Restoric Design, contractors can breathe a sigh of relief. A number of daunting tasks can be cut down by assigning elements to facilitated members, and the software can even accommodate fabricated parts into a model so you can continue editing and modifying smoothly.

Steel shop drawings can be generated to provide detailed and comprehensive construction documentation. And with the ability to comprehend the overall constructability of a project right from the outset, you can be as efficient as possible on the scheduling and cost of construction. This impacts the execution of every stage of construction, and you can explore a range of options before commencement. Structural detailing enables flexibility of simulations, giving you better control over your project.