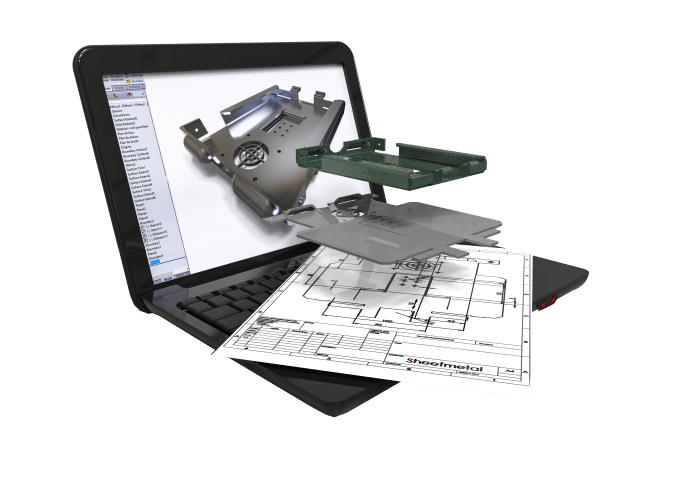

CAD has become one of the foundations of all types of engineering, and as such CAD software is undergoing constant development to make it easier, more efficient, and more feature intensive. Despite this, there are still several common and recurring complaints that CAD users have when dealing with CAD software.

This is why outsourcing your requirements to a CAD services provider makes so much sense, because it means you get to avoid dealing with the fallout from these irritations interrupting your workflow and causing endless frustrations.

Here are some recurring frustrations CAD engineers encounter, and how outsourcing means you can avoid them.

Unintuitive design

It’s a common bugbear of CAD software that it doesn’t offer an intuitive interface, particularly to first time users of the software. Simpler examples of CAD software do exist, but they’re generally less popular because they also have fewer features and are less powerful.

Through outsourcing, however, you don’t have to worry about this. Your CAD services provider will already be familiar with the CAD software necessary for your medium. That means time is spent learning software which can be better spent on actually developing your project.

Computer performance

As the size of your CAD requirements increase, so too do the minimum computer specifications required to run the software reliably. All CAD and CAM software will list the necessary minimum computing power required, but it can quickly become an expensive process if you need to upgrade your equipment in order to run the program properly.

Outsourcing to a CAD services provider, on the other hand, means that they already have the computing power in place to efficiently run the CAD software at the required settings for the size of your project. This means project development is not impeded by slow running programs and unresponsive inputs.

CAD intercommunication

CAD is just one stage of the design process, which means in order to transition from design to finished product your CAD software is going to have to communicate with other programs. The difficulty is that some programs don’t communicate very well and getting files transferred from one piece of software to another can be time-consuming, and in the case of the software not reading the file properly, may result in manufacturing faults.

Your CAD services provider will already have a list of programs they regularly use which they know communicate in the most efficient way possible. This means that time is saved in the project design process, and you have the peace of mind that comes from the manufacturing plans being exported accurately.

Cost of ownership

CAD software is highly specialised and as a result, the software itself can be a considerable investment. There are free CAD programs available, but they often lack the features and necessary performance for commercial applications. If your business doesn’t use CAD that often or you don’t have employees familiar enough with it to make the best use of its potential, it can be a drain on your resources.

Outsourcing then becomes a valuable alternative for businesses who don’t want to invest in the necessary software and training for efficient CAD usage. Your CAD services provider will already have the software and employees fluent in its use, meaning you save both time and money in the long run.

Consider outsourcing your CAD projects

The CAD process is one where you want to improve efficiency as much as possible. Unless you already have an employee fluent in its usage, you can save a lot of valuable resources by outsourcing to a trusted CAD services provider.