Steel detailing is an extremely important facet of structural engineering and requires virtually 100% accuracy. Any tiny drawing mistake or mathematical error can lead to major problems in construction and loss of time and money. Although architects and structural engineers are responsible for approving all steel detailing, ultimately the success of major steel fabrication projects relies to a great extent upon the professionalism and accuracy of the detailer providing drawings.

The use of structural steel detailing is essential for a wide range of construction and manufacturing purposes, including the building of commercial and residential buildings, shipbuilding and warehousing of factory construction.

What does steel detailing entail?

Steel detailing entails drawing up detailed plans for builders, contractions, construction teams and professionals involved in the construction process, as well as any required estimates, reports and other critical activities. It is a complex drawing office role, as drawings need to be framed so they are understandable at the construction levels and will not just be read by the professionals involved in the overarching design of projects.

Two types of drawings are needed: shop drawings (detail drawings) and erection drawings and these are discussed in some detail below:

Shop drawings

Shop or detail drawings include specifications for each individual piece of steel that will be used within the fabrication process. This will include the columns, joists, beams, braces, and trusses that will be made by steel fabricators. All drawings will need to include component sizes, material specification, surface specifications, sizes, and dimensions, painting details and information about the welding and bolting that’s required. Any additional detailing for components will also need incorporating so steel fabricators are fully advised of all requirements of the job. Shop or detail drawings don’t relate to the erection or installation of any steel, however, but are purely concerned with the planning of successful fabrication processes.

Erection drawings

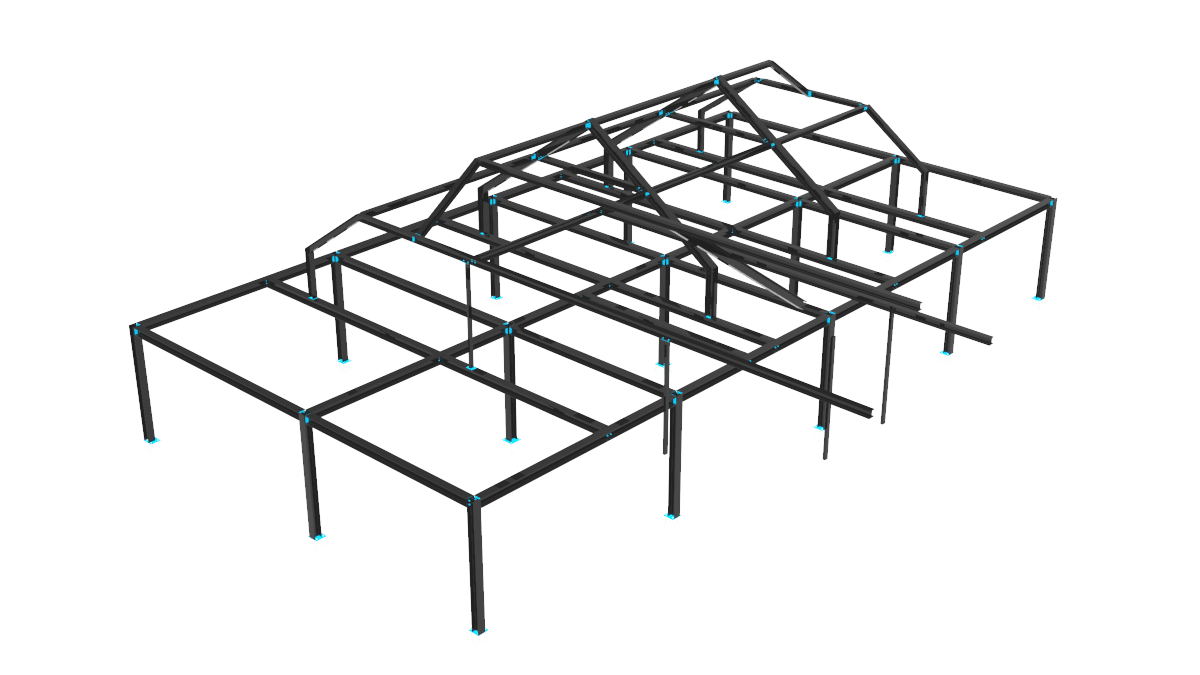

The erection drawings are needed in order to show dimensioned plans of structures, alongside exactly where and how each particular steel component fits into the construction and overall structure. The drawings will contain detailed information with regard to positions of components and all installation requirements. If there is any need for additional works, like fitting bolts, welding or anchors, this will also be flagged within these complex erection drawings.

Other critical building stages, like reinforcing details, anchor setting planning, steel design, and connectivity planning will also be included within a set of erection drawings.

Global standards for steel detailing

Different global steel detailing standards operate around the world and it’s important to comply with all regulations that apply to specific locations.

Some of these standards are specified by the following regulatory bodies:

American Institute of Steel Construction (AISC)

National Institute of Steel Detailing

American Welding Society (AWS)

Australian Institute of Steel Construction

Canadian Institute of Steel Construction

UK standard codes and European standard codes

Approvals for steel detailing

Structural engineers are responsible for the integrity, strength and final design for steel structures, however, the associated architect for the project will be responsible for ensuring all building codes and dimensions are correct. The steel detailer handling drawing up plans will, therefore, need to take responsibility for receiving approval from both the architect and the structural engineer for all supplied steel detail drawings. These approvals need to be in place prior to the commencement of any structural steel works on sites.

Restoric Design provides professional steel detailing to the specified standards in any area of the world. We’re expert at providing the accurate steel drafting needed to ensure critical construction projects meet planned objectives and clients don’t experience delays. Get in touch to discuss all the benefits of steel detailing from Restoric. We also offer a wide range of additional drawing and drafting services using all the popular drawing office software currently on the market.