The steel detailing process in brief. The steel detailing process goes something like this:

Step 1: Reviewing the existing drawings

The steel detailer must review all the structural engineer and architect drawings to gain a profound understanding of the proposed structure. It is essential for the detailer to get a full picture from both sets of drawings in order to do their job effectively.

Step 2: Developing steel detailing drawings

The steel detailer develops comprehensive ‘instruction manuals’ for both the fabrication shop and the crew that will erect the structure on site. The job of the steel detailer is to make the processes of fabricating and installing the steel as swift and simple as possible, but they must do so without breaking any of the constraints specified in the drawings of the architect and structural engineer. And, of course, all the safety rules must be adhered to as well.

It is the responsibility of the detailer to identify any information in the required constraints that are either unclear or conflicting, and to then formally resolve the issue by coordinating with all the relevant parties.

Step 3: Presenting the final steel detailing instructions

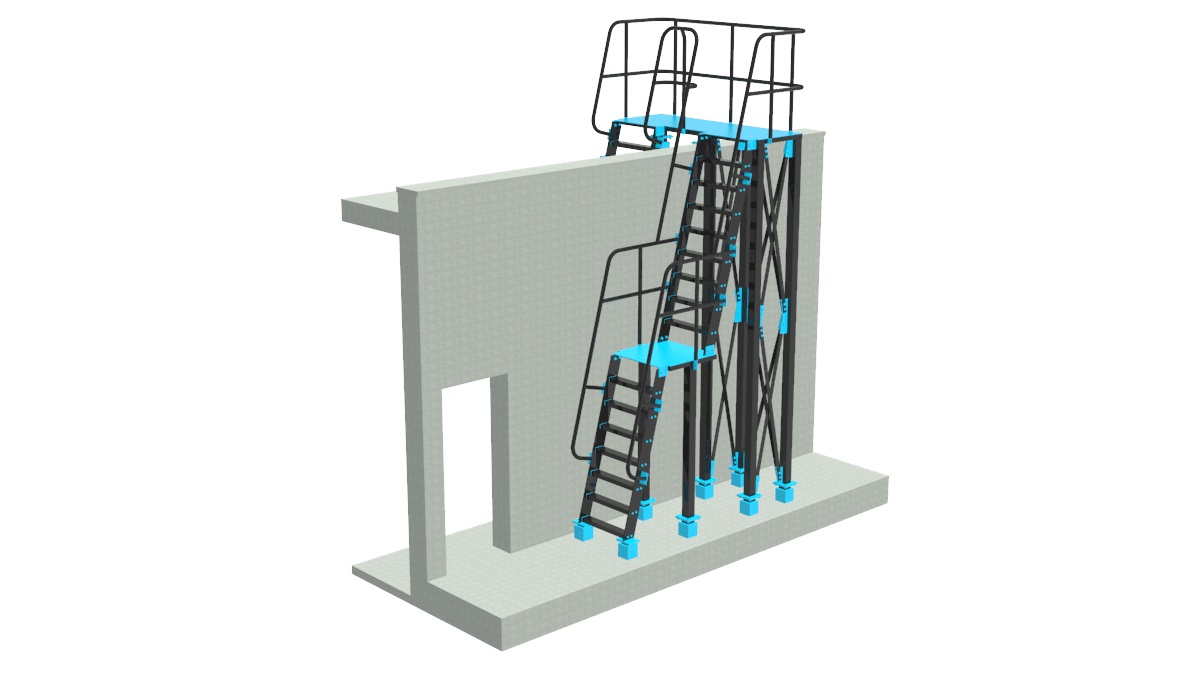

When the process is complete, the steel detailer will have produced two sets of clear, beautiful ‘instruction manuals’. The first set of drawings and instructions directs the shop on how to create every component of the structural steel. This will include where the holes must be placed, the welding of the connection plates, paint, finishing and everything in between.

The second set of drawings and instructions are intended for the field crew responsible for erecting the steel structure. These drawings are reminiscent of the assembly instructions that come with a flat-pack furniture purchase from a department store. The entire process is considered a success when all the holes line up perfectly with the connection plates. All the physics, mathematics and logistics should have been addressed in step 2 of the whole process and reflected in the final set of drawings.

Making the right choice

As you can see, the work of the steel detailer is absolutely pivotal in ensuring a construction project goes off without a hitch. The last thing you need during the erection of a new structure is to find that there were errors in the steel fabrication or certain components are not fit for purpose. These kinds of errors come from inferior steel detailing, and can cause significant delays that also represent a substantial hit to a project’s budget.

Avoid these kinds of issues by taking the time to carefully select the right steel detailer for your project. At Restoric Design, we are a steel detailing firm whose reputation speaks for itself. When you outsource your steel detailing to us, you can rest assured that you are working with the right partner to get the job done. We would love the opportunity to impress your company, so get in touch today and we’ll get down to business.