The flexibility to achieve curves and angles

Where curves and angles in a design are complex, CFS can be the answer. In Washington, USA, an iconic feature of The Wharf consists of 108 condominiums. It was primarily formed with 9,000 lineal feet of CFS wall framing that is load-bearing, integrating complex curves and angles to create a semicircle that fits perfectly with the surrounding streetscape. CFS was also applied to support a tower that includes floor-to-ceiling glazing, further demonstrating the flexibility when the steel detailing is done right.

Strength for soaring volumes

When architecture needs to inspire and engage, architects frequently turn to awe-inspiring spaces with vast volumes, many of which are not suited to wood frames and concrete construction. CFS is the ideal solution for this, as it’s able to support giant spaces with oblique shapes and creative angles. When you need to impress with your buildings, steel detailing for CFS structures can accommodate your less conventional ambitions.

The versatility for specialised features

When you want to incorporate real innovation and ingenuity into a design, you will probably find yourself with complex needs for exterior walls. With CFS detailing, you will be able to support unique visual features that can even give a physics-defying appearance to amaze onlookers. CFS frames can combine with structural steel beams to support challenging loads, with complicated alignment and bespoke connections which a good steel detailer can help with. You shouldn’t have to reel in your vision, and with CFS detailing you can bring your most innovative designs to life.

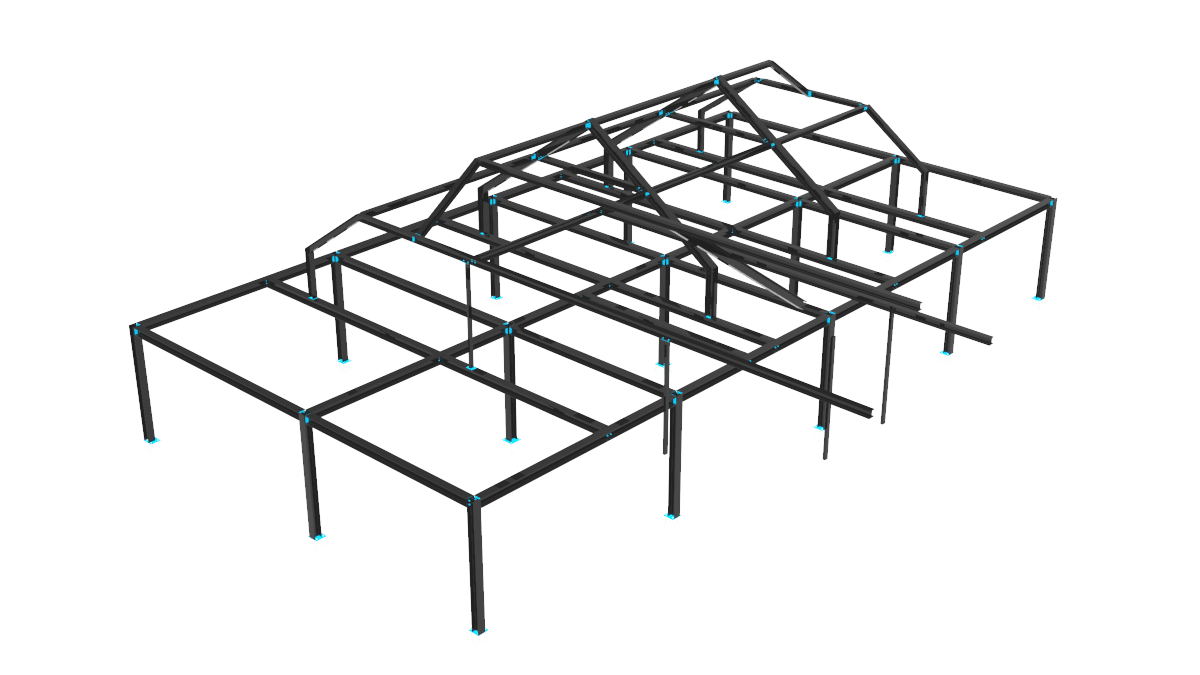

Unique qualities for longer spans

Large, uninterrupted spaces are important for event venues and assembly halls. CFS detailing has played an important role in the design of structures that deliver on this front, such as public venues, arenas and religious buildings. Large CFS trusses can provide the necessary strength for large spaces and meet deflection requirements for the vast, heavy roofing that is required. When internal openness is a fundamental requirement, steel detailing using CFS can help deliver on structural and aesthetic goals that may not be achievable with other construction materials.

Precision

Many components of architectural design require great precision, and CFS excels on this front. The components will be prefabricated from the steel detailer’s drawings, designed to exacting standards in an environment that is protected against the elements. And the uniformity, durability and dimensional stability of CFS means you get that quality for the long haul. When stringent quality tolerances are part of the design spec, the incorporation of CFS detailing can deliver the precision you need to get the right results – consistently meeting tolerance needs with prefabricated CFS panels.

Architecture is a competitive and rapidly-changing sector, and architects need to deliver on time- and money-saving solutions for owners whilst pushing their own innovative and creative boundaries. Restoric Design is a steel detailing subcontractor that can help deliver on these needs with CFS detailing, modelling and instructions for prefabrication. So whether your designs incorporate classic, traditional design elements that blend into their modern surroundings or innovative elements designed to challenge the status quo, when you work with Restoric you have a quality partner that will produce the goods every single time.