One of the most critical components of steel detailing is connection design. It is the part of the process that ensures that things hold together as they should.

Architects are constantly coming up with new and challenging designs. To get buyers for their ideas and concepts, architects’ creations have to be aesthetically pleasing. You only have to take a look at the competition for the UK’s most exemplary buildings in London run by the RIBA Chartered Architects and RIBA International Fellows organisation to see what we mean.

Last year there were 200 entrants from which a shortlist of 83 was drawn up. This was for London only. Similar competitions and award ceremonies take place each year in major cities all over the UK.

Taking architectural design to the highest level

Celebrity buildings like the Arcelor Mittal Orbit, City Hall (on the banks of the Thames), the Gherkin, the Lloyds Building and the Shard, take building design to its highest levels. In doing so, they present unique challenges to companies like Restoric Design, who specialise in steel detailing and connection design.

Without top-quality connection design services, the completion of such building projects would not be possible. Tall heights and odd shapes make extraordinary demands on the steel framework that sits hidden behind a sleek exterior.

The need for accurate steel detailing and connection design is widespread

Of course, producing steel detailing and connection design isn’t just a challenge for celebrity buildings. It is necessary for more ordinary building projects too; things like factory buildings, blocks of flats with feature balconies and bridges. They all require accurate, reliable steel detailing and connection design to ensure lives are not put at risk.

At a fundamental level, the connectivity element of steel detailing is what is used to calculate the transference of forces between sections of steel. Basically, these forces fall into one of four categories: Beam to beam, bracing connections, column to beam, and splice.

Marrying steel connection suitability with construction best practice

Connectivity design isn’t just required to ensure that a connection doesn’t fail with relation to its specified load detail. It must also take into consideration the needs of fabricators and erectors when manufacturing and installing the various elements.

Verification within the steel connection detailing process must cover proving the integrity of welds and that the stresses put on steel plates, sections, and the bolts holding them together are all well within the stress tolerances of the materials that are specified. Once all of these calculations are complete, they are then presented in the format of a report.

FEM/FEA methodology

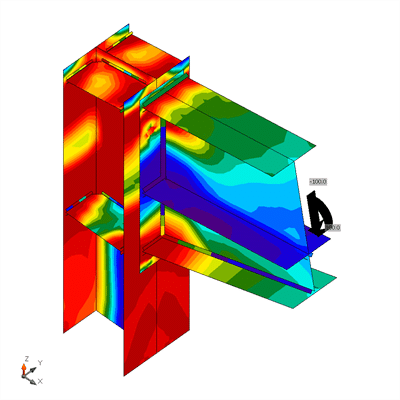

Here at Restoric Design, we have special steel connection design software that we employ in the process of carrying out steel detailing. The program we use helps us to calculate the stresses that will be exerted using the finite element method (FEM), which is also sometimes referred to as the finite element analysis or ‘FEA’ for short.

Once we have calculated the connection or the types and parameters of the loads, we then take note of the preferred methods the fabricators and installers specify, and design a suitable connection. The loads are then approved by qualified structural engineers to verify the calculations.

All bolts, plates and the welds themselves are detailed according to their particular stresses and loads to confirm that they are well within the characteristics of the chosen materials.

Reasons why you should use Restoric Design

Choosing the right company for your steel detailing is key. If you decide to employ the services of Jansen Consulting, here are some of the benefits you will enjoy:

• Our processes are certified under ISO 9001

• We employ a team of experienced, highly qualified detailers

• In excess of 700 projects completed to date

• The diverse policies and standards we follow underpin our liability insurance

To get an idea of the professional steel detailing services we provide. Please check out the “Projects” page on our website. It is sure to impress.