Steel detailing is undoubtedly one of the most important disciplines in structural engineering and manufacturing. Used in numerous sectors, including commercial and residential architecture, infrastructure and shipbuilding, the process requires incredible accuracy and skill.

The steel detailing will communicate vital information between architects, structural engineers, building regulators, contractors and fabricators, making it a critical project management tool. Even the smallest error can put a project’s budget and timeline in jeopardy, so it is essential that these drawings are drafted by an experienced professional. Below, we give an overview of its features and explain why steel detailing is a vital tool for each stakeholder.

The components of a steel detailing draught

Steel dealing communicates critical information between the key players in architectural or engineering projects. These drawings need to be fully comprehensive, incorporating plans, estimates, report data and a list of essential tasks. As such, it is a central reference point for project management. These plans are divided into two principal types of drawing: shop drawings and erection drawings.

Shop drawings

Otherwise known as detail drawings, the shop drawing will outline the features of every individual steel component in the structure. These could include columns, joists, beams, trusses, or any other steel piece in the project. These drawings will also contain material specs and surface specifications, as well as sizes and dimensions. Thus, the shop drawing is essential information for the steel fabricator.

However, the importance of the shop drawing extends beyond the individual parts. This drawing also contains important information about welding, bolting and painting details that will be vitally important when the structure is on-site, so the fabricator has to make sure their designs align with these specifications.

Erection drawings

The erection drawings are the other key component of a steel detailing draught. Once the fabricator has produced the parts to the shop drawing specifications, the on-site contractors will use erection drawings to place each steel piece within the structure. As such, the erection drawings focus on the placement of each component, the instructions for their installation, including the placement of bolts, welding spots, and wedge anchors.

Producing steel detailing drawings

Once, steel detailing drawings were created by hand. Naturally, the demand for accuracy and reproductions has meant that computer-generated drawings are the industry standard. Now, specialist software designed specifically for this purpose aids in the production of these drawings.

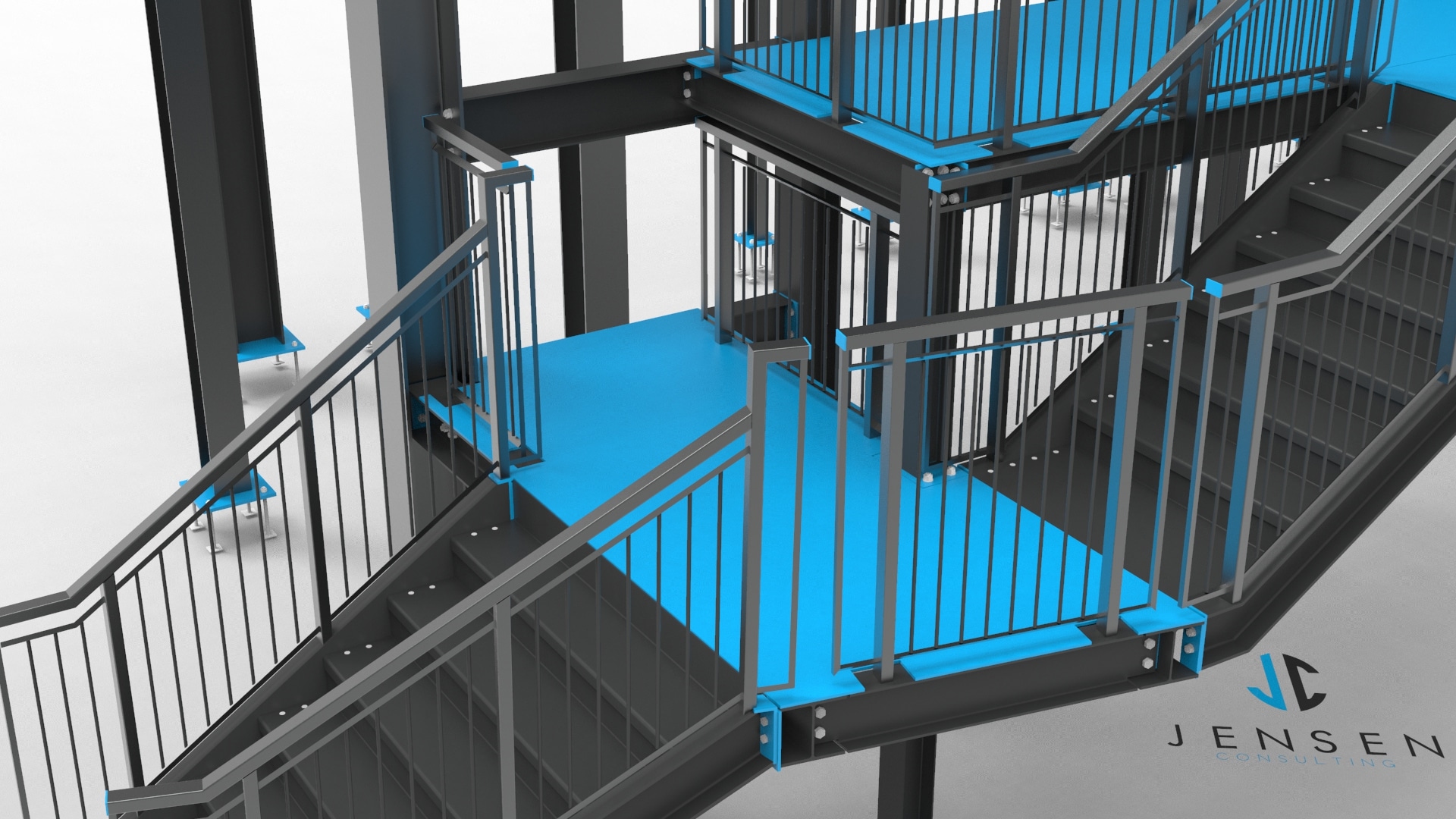

This means the steel detailer’s skillset has shifted. Now, they need to be highly skilled users of 3D modelling applications and CAD drafting software. In fact, this is quite a different skillset from 2-dimensional modelling, requiring far more collaboration. In most projects, the entire structure will be draughted in 3D before construction begins, so the steel detailer will work with a cross-functional team of CAD modellers.

Moreover, this drawing will also play a direct role in methods deployed by the fabricator. Now, fabricators use Computer Numerically Controlled (CNC) files to automate their cutting and drilling process. As such, the accuracy of the steel detailer’s drawing has a direct, real-world effect on the fabricator’s role.

Why steel detailing is the lynchpin of a construction project

Computerisation means that the steel detailing process is even more integrated than ever before, making it the lynchpin of a successful construction project. Thus, steel detailing is an essential tool for the entire project team, providing instructions to fabricators and contractors, and accountability to the structural engineer, architect and building regulators.

Therefore, the steel detailer has an integral role in the entire project, and indeed, a critical role to play in connecting the whole team. They link every team member, from the structural engineer to the general contractors to ensure entire the project is structurally sound. Now, a once discrete role has an interconnected, networked role to play – making accurate steel detailing vital to all aspects of a project.