You might not have heard of steel detailing before but it is an essential step in many architectural projects and building design.

What is steel detailing?

Steel detailing is a preliminary step in the construction planning process, whereby a steel detailer creates comprehensive drawings and diagrams, which will then be used by steel fabricators and steel erectors during the manufacture and erection of steel, mainly as part of commercial and industrial builds, but also a part of residential projects.

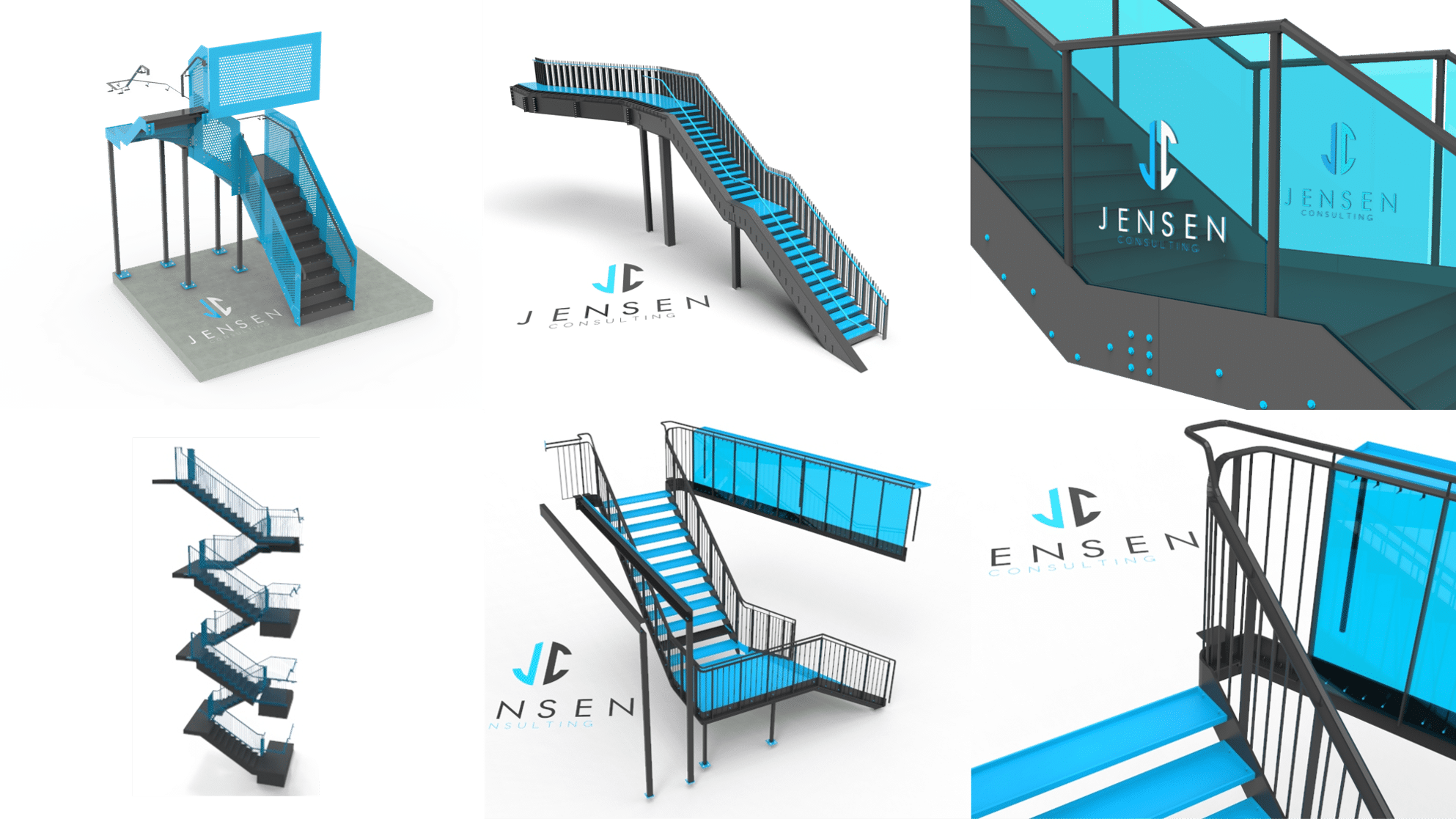

We are experts at using steel detailing for staircases, balconies, balustrades, mezzanine floors, bridges and steel frames for buildings.

Steel detailing for staircases

In today’s modern commercial and residential buildings, there are many types of steel staircase that are frequently seen, such as straight, curved, spiral and u-shaped stairs – all with different tread profiles and finishes to choose from.

As well as looking good and fitting with the design of the building and the rest of the interior, all designs need to comply with building regulations. In this article, we give an overview of the four main types of steel staircase you can choose from.

4 types of steel staircase designs

Straight

Offering a straightforward construction process, straight stairs are the simplest design and will work in many contexts. They are generally an affordable option and used where time is limited. Individual designs can be customised with handrails, glass panels and other additions for improved aesthetics.

Spiral

A spiral staircase can make a real style statement in a modern home or office environment. They are not only attractive but very compact, making them a great option where space is limited, for example, leading up to a loft conversion in a city home. The designs can vary but in a spiral staircase design, the treads always encircle a central pole.

Curved or helical

These are often mistaken for straight stairs but on closer inspection, they can be identified as curved stairs, as they follow a gentle arc shape. The design usually includes two rolled stringers, with the treads placed in between.

U-shaped or switchback

A u-shaped design includes two sets of straight stairs interconnected by a small platform or landing, which allows for a 180-degree turn. They are often found in blocks of flats or offices and are often referred to as switchback stairs or half turn stairs.

How does the steel detailing process work?

When it comes to the time to create your steel detailing drawings, we will start by producing a 3D CAD Model using the leading software application, Advance Steel, based on drawings given to us by the architects.

Using this 3D CAD Model, we then produce a General Assembly Drawing for approval. The GA Drawing encompasses all relevant views – plan, elevation, sections – as well as the connection details.

Once we have gained approval based on the GA Drawings, we make any necessary changes based on your feedback and feedback from all relevant parties.

After approval, it is time to produce drawings for the individual parts, detailing assembly, in addition to material and bolt lists and NC Files.

What will you receive after a steel detailing project has been completed?

All clients receive a Fabrication Pack, which includes everything needed to order, fabricate and erect the steel structure or structures for your staircase.

Within each pack, there are comprehensive erection and assembly drawings, in addition to drawings of each individual part and a full list of required materials and bolts required. As well as this, there are DXF Files for laser cutting plates and NC files to aid cutting and punching of the different sections.

If you would like advice on creating a steel staircase contact us today.