When most people think of CAD and CAM today, they think of 3D printers or ultra-precise machining. After all, we live in a 3D world, so the concept of 2D CAD can seem outdated. However, there is still a range of use cases for 2D CAD drafting, including mechanical, electrical, and plumbing services. The advent of 3D computer-aided design and manufacturing services might have made some applications of 2D CAD drafting redundant, but it is still an essential option for several reasons.

Ease of use

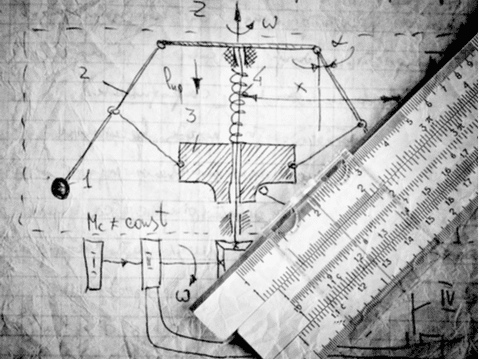

3D models can be very helpful for aiding the visualisation of a final product during the design process, but they aren’t always necessary. Things like schematics, component and piping layouts, and other MEP drawings all favour a 2D format and are still widely used by the construction industry.

Adding a third dimension to designs can be beneficial in many instances, but not when a two-dimensional diagram already does the job perfectly well. The extra capabilities of 3D CAD software require tools and features that aren’t present in 2D CAD software, where they would just get in the way. 2D CAD is much easier to learn and use than 3D CAD.

Flexibility

Another benefit of working with 2D CAD is that it’s much easier to amend designs when necessary. Making even relatively minor adjustments to a 3D model can be time-consuming, and there’s much more room for unexpected complexities to arise. Because of this, 2D CAD work lends itself much more to experimentation. With just a few clicks, you can completely alter any aspect of a 2D schematic.

The ability to change 2D schematics so quickly and easily is also a godsend to anyone who remembers the days when these things were produced by hand. Not only are digital schematics considerably easier to alter and play around with, but they are also perfectly accurate every single time.

Fewer errors

2D CAD software makes most manual calculations involved in mechanical, electrical, and plumbing work redundant. And where manually-calculated figures are used, any errors will quickly become apparent when they’re entered into the CAD program. What’s more, when a designer alters their designs within a CAD tool, the software will automatically adjust other values affected by the change.

The end result is that 2D CAD enables schematics and other similar designs to be produced faster and more accurately. These benefits are particularly important when you’re looking to iterate on an initial design rapidly.

Save time

The CAD software handles most of the calculations on the designer’s behalf and requires relatively little manual input, leaving them free to focus their attention on more important areas. Where multiple schematics or designs are used in conjunction with one another, there’s less room for human error and issues down the road. Because 2D CAD drafting is digital, the resulting designs are easily sent between different teams and individuals, ensuring everyone stays on the same page.

By dramatically speeding up the initial design process while also reducing the error rate, 2D CAD drafting accelerates the process of designing, manufacturing, and detailing finished units.

Cost-effective

2D CAD systems are much, much cheaper than their 3D counterparts. And because 2D CAD is inherently much simpler than 3D CAD, the costs of hiring a 2D CAD expert to produce your output for you are significantly smaller than they would be for an expert in 3D CAD. The reduced scope for human error that 2D CAD offers further improves its cost-effectiveness compared to previous methods of producing schematics.

Restoric Design offers both 2D and 3D CAD services for customers in multiple industries. Our commitment to quality work, excellent communication, and customer satisfaction make us one of the best options out there. Contact us today to find out more about how our services could benefit you.